1. About 3D design and printing

1.1 Introduction

3D printers are based on the rapid prototyping (RP) technologies of the 1980s used in the industrial market. Today, due to patent expiry, 3D printing technology is becoming increasingly available to consumers.

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. It uses a printer like machine which melts a material (commonly plastic) and pours it on a base in a predefined manner thus creating successive layers to make it 3 dimensional.

1.2 Process

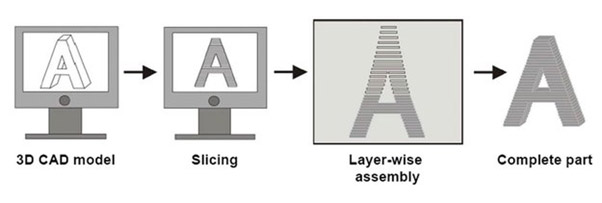

For any 3D print to take place the following are the four simple steps to be followed:

– 3D CAD modelling

– Slicing and other settings

– Layer – wise printing

– Complete part

Image 1.1 Main steps of the 3D Printing process [source]

Image 1.1 Main steps of the 3D Printing process [source]

1.3. Uses

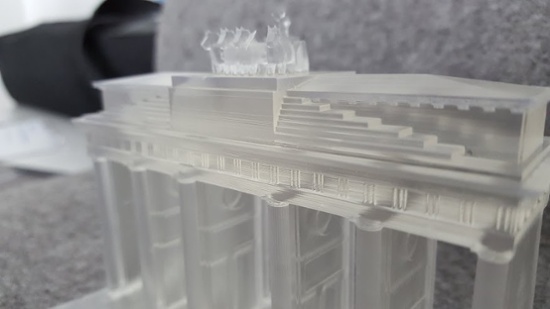

First of all, you may wonder why somebody would want to print something in 3D. The first reason is the most obvious: because the possibilities are endless. The most common reasons for businesses and institutes to invest in 3D printing solutions are to achieve rapid prototyping, to visualize architectural scale models, to improve healthcare (there have been experiments with 3d printed prosthetics and printing with human tissue), to optimize engineering processes and to replace machine components, etc. But there’s even more. You can even print candy.

Image 1.2 A 3D print of the Berlin Brandenburg Gate [source]

Image 1.2 A 3D print of the Berlin Brandenburg Gate [source]

Sources:

[1] https://www.allaboutcircuits.com/news/introduction-to-3d-printing-history-processes-and-market-growth

[2] https://circuitdigest.com/article/beginners-guide-for-getting-started-with-3d-printing

[3] https://www.3yourmind.com/blog/what-is-3d-printing