10. New artisan working methods – Molds

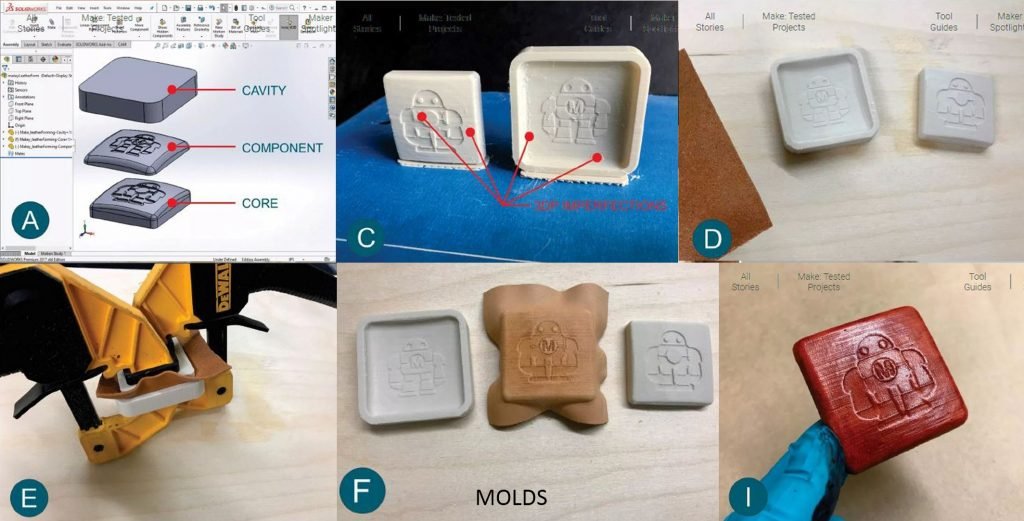

In the following pictures, a “Makers Fair” logo mold has been made. To make a mold is necessary to know very well the technological properties of the material the mold will be applied on.

First of all, a model of the final piece and a negative mold has to be created through 3D modeling software: the top part will show a cavity impressed with the desired pattern, while the underside will show a relief of the same pattern. After 3D printing, both of them have to be sanded and cleaned to obtain a smooth surface, the leather has to be moisturized and some pressure applied. Then the piece can be finished by trimming borders, dying and conditioning.

Image 10.1

References:

[1] https://makezine.com/2018/07/09/use-3d-printing-shape-leather/