11. New artisan working methods – Shoemaking

In the case of shoemaking, new technologies changed completely the traditional working methods. Shown below you can see an Earl Stewart project called “The Bit Shoe”. It includes both traditional and innovative way of working: the sole has been created by 3D scanning the sole of a foot, then it’s been 3D printed in a net pattern that gives the surface enough elasticity to follow the foot movements. Innovation meets tradition on the top part of the shoe, made with laser cut leather.

Image 11.1

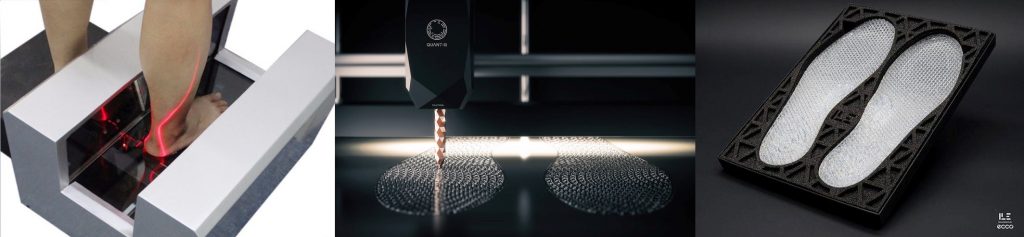

We can find another exemplary use of 3D scanning and printing in a product “Ecco” trademark invented: a 3D printed silicon midsole that ensures the customer comfort in wearing. To create it they analyze through tests and 3D scanning the customer sole of the foot; they also sell shoes, so over the common product, customers can choose to have a personalized midsole with an overprice.

Image 11.2

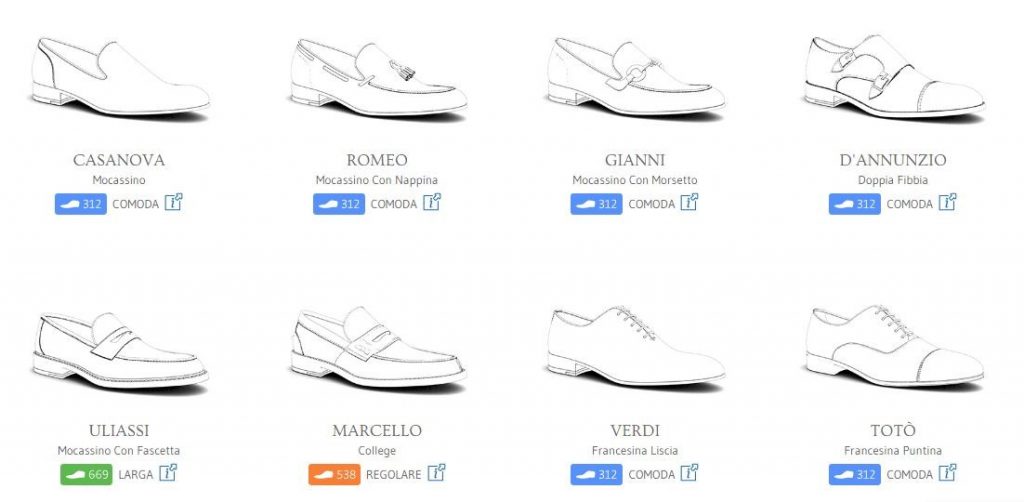

Another trademark that involves technology in its production line is “DIS“, Design Italian Shoes. They provide the shoe shops a device they call the Totem Touch Screen. “Customers place their feet in the bottom of this device to have them scanned. They then use a touch screen to select a style of shoe and to customize it, from colors to materials, types of sole and even the eyelets and laces. Some 50m combinations are available. Personal monograms and inscriptions can be added too.”

At this po,int technology meets traditional work: the 3D scan is sent to the Italian trademark and the components are produced as requested by acknowledged artisans in central Italy in ten days.

Image 11.3

References:

[1] http://www.spicytec.com/2013/06/3d-printed-hybrid-shoe-concept.html

[2] https://www.economist.com/science-and-technology/2018/05/24/shoemakers-bring-bespoke-footwear-to-the-high-street