13. New artisan working methods – Glass

In this sector, traditional working methods are still the most diffused, but never-ending curiosity brings us some examples of how 3D printing can be applied in this field too.

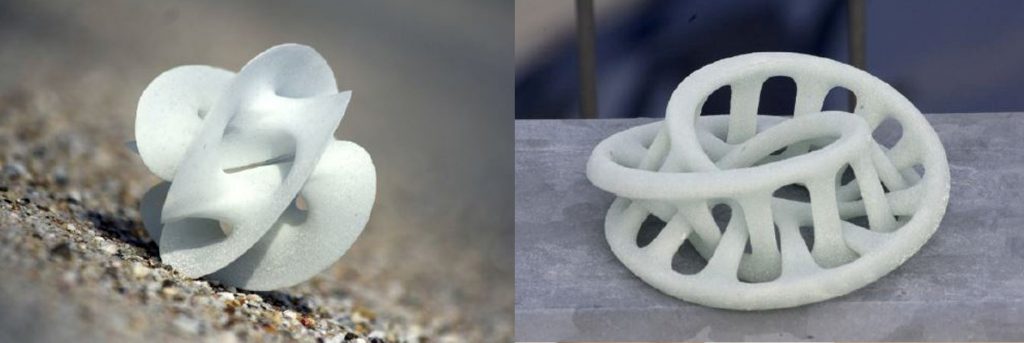

In the first case you can see a structure realized with recycled glass; it’s been modeled on a 3D software, then it’s been 3D printed using glass powder and a binding solution that gives it enough strength to keep the structure together, then it’s fired and the binding gets fused to the powder leaving a compacted glass structure a final result.

Image 13.1

In the second case, you can see a real example of a 3D printer for glass. The initial process is the same of those already seen, so a 3D modeled shape is needed. Here the knowledge of the material is meaningful: to flow well enough to be extruded through a nozzle, the glass ink has to be kept at a temperature greater than 1000 °C (1832 °F), so the environment the structure has to be kept in has to be well heated and well organized to allow a slow cooling and safety in working.

To achieve this, the printer needs separate heating systems for each stage of the manufacturing process: the molten glass ink passes through a heated crucible that keeps the desired temperature, then through a custom nozzle where separate heating coils keep it hot enough to flow without sticking to the inside, finally objects are built inside a third heating chamber kept just above the temperature at which glass turns solid. This allows the printed objects to cool down in a gradual controlled way, so they don’t break.

Image 13.2

References:

[1] https://www.shapeways.com/blog/archives/401-you-can-now-3D-print-in-glass-with-Shapeways.html

[2] https://www.technologyreview.coms5409263-d-printing-breaks-the-glass-barrier