14. New artisan working methods – Ceramics

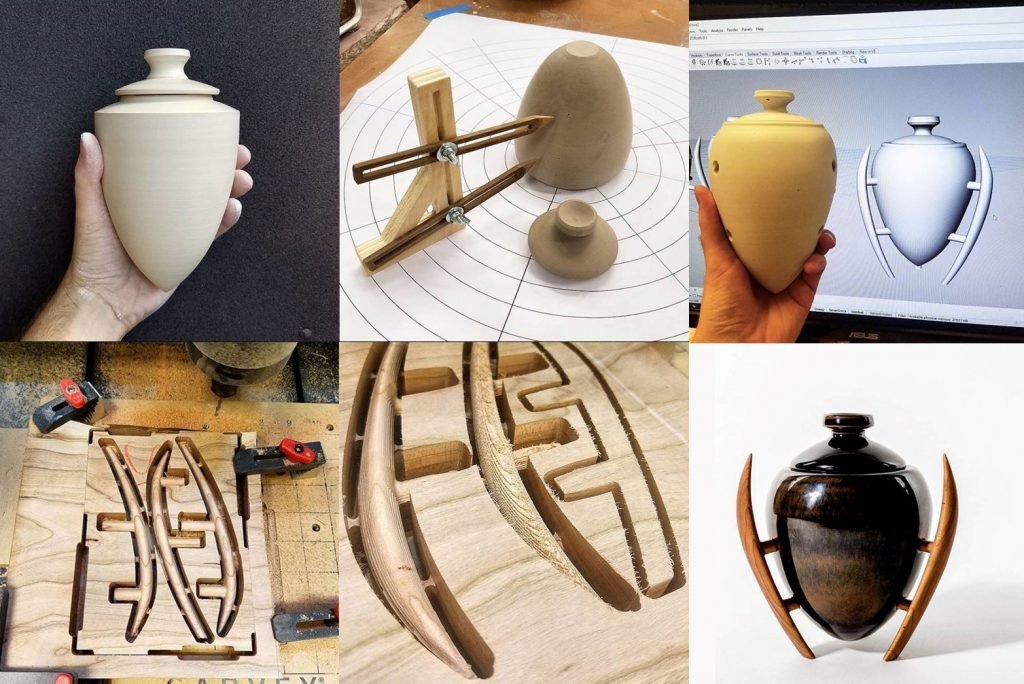

In this field mostly traditional techniques are used too, but here’s the exemplary case of Curt Hammerly from Colorado, USA,(Hammerly Ceramics on Instagram), who used 3D modeling and 3D printing in order to create a new design for vases and other artifacts.

He created the shape he was interested in with a 3D modeling software, then made a negative model, keeping as an aim that one to create its mold. he 3D printed one of the four identical parts constituting the whole mold, then made a silicon cast to make plaster replicas of the initial piece, creating four final “cloves” to build up a plaster endlessly reusable mold. Finally, he poured semi-liquid clay in it, then let it dry for a while, set apart the excess of material, let it dry again, take the shape out of the mold, fired it in the oven, then glazed and fired it once more obtaining an original vase as final shape.

Image 14.1

In the second case, he wanted to create an urn using ceramic for the “body” structure and wood for the handles. He created a tool to take precise measurements on his artifacts. After making the “body”, he made the holes the handles would have to fit in and he fired it, then made a model of it in a 3D software creating the handles too; the project of the handles was sent to a mechanical milling machine which milled them out of a wooden panel, keeping some bridges to keep them still, then finally the two pieces of wood were sanded and refined by hand, the urn’s “body” was glazed and fired for the last time and all the pieces were stuck together getting a nice final effect.

Image 14.2

Let’s keep being curious about what surrounds us and let’s remember that not so much is needed to create a quality product: let’s keep alive our creative flair, our technical skills and our knowledge. That could be enough.