2. Recent developments in the craft field advanced by new digital technology

2.1 Introduction

The introduction of information technology and the use of modern 3d modeling and printing technologies have revolutionized the field of handicraft production, from design to the production of objects, which can range from a piece of furniture to a piece of jewelry, from a leather bag to a ceramic vase.

More in detail, 3D printing, which in recent years has become accessible to everyone especially for rapid prototyping, thanks to the advent of increasingly economical and efficient printers, has become a strategic tool in the artisan production.

2.2 Handicraft

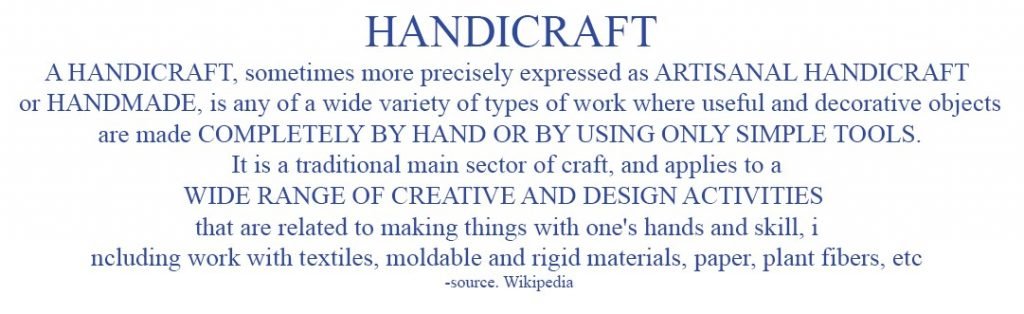

First of all, it is useful to specify what we mean by “handicraft”, and it is possible to start from the exhaustive definition given by Wikipedia.

Image 2.1 [source]

It is also correct to specify that the handicraft must have a high degree of manual skill, is aimed at the production of unique pieces or limited series of objects and semifinished products can also be used as they only perform an ancillary function.

2.3 List of common handicrafts

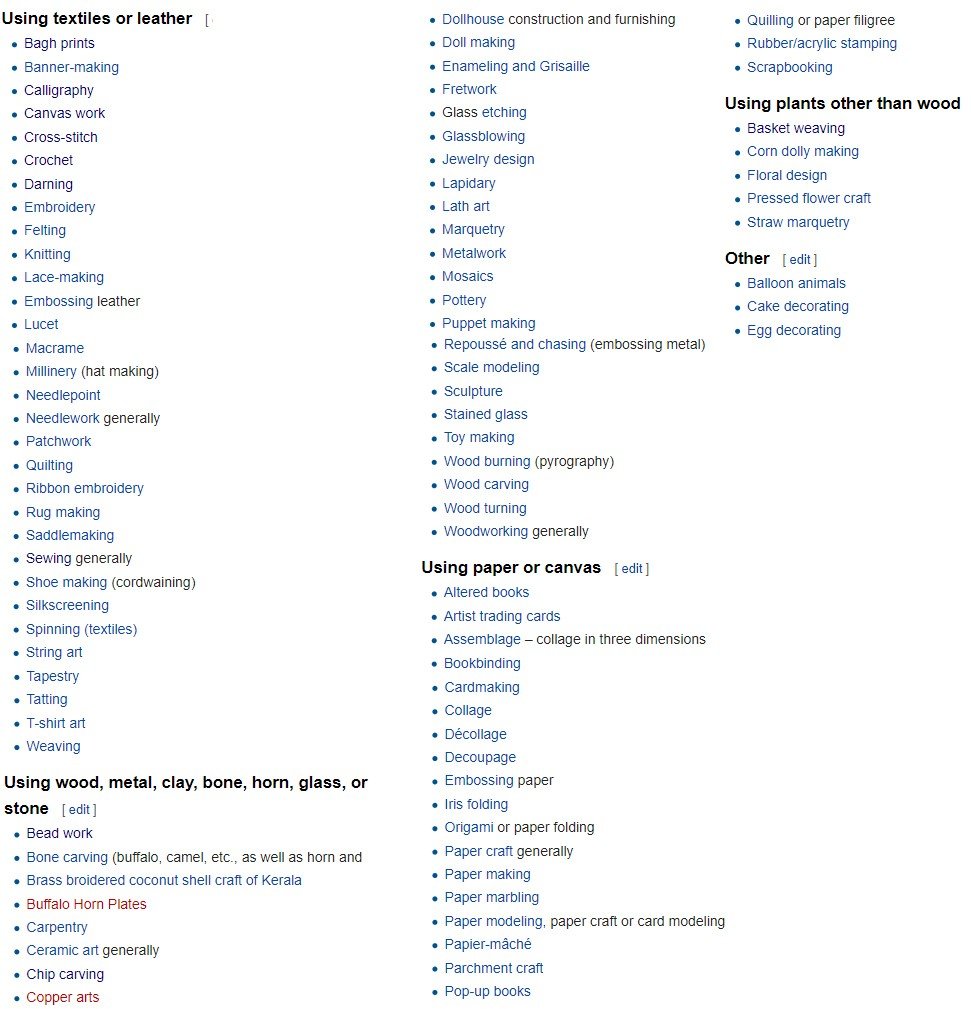

The field of work embraced by handicraft is ample, it is probably impossible to list all the jobs that can be defined as handicraft. However, they can be subdivided according to the type of material that is used in the processing, also in this case what is reported by Wikipedia is a valid help to get an idea of the vastness of the topic under consideration.

Image 2.2 [source]

Therefore, simplifying:

Image 2.3

2.4 Common traits in handicraft production

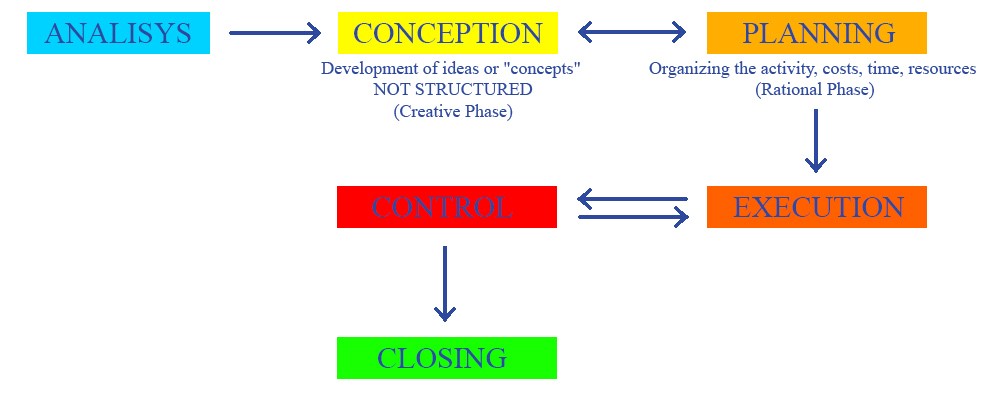

Considering that the production processes vary from work to work, it is possible to indicate a simplified general scheme of the project/production process common to all:

Image 2.4

The first phase, called “Analysis”, is the step in which gather information, observe the world, the needs of people and their tastes. Analyze the reference market and the competitors, get updated on new technologies, new materials and research. From this stage, they get information for “Conception” and “Planning”.

The phase called “Conception” is the step in which the idea is studied, the creative phase where the object is defined, features, the shape, the colors, the materials, the finishings. The products of this phase are sketches, visions, concepts and prototypes.

The phase called “Planning”, after defining the idea and the object to be realized, plan the phases of production, timing, personnel, activity, costs, sales channels. This phase can be before the “Conception” phase, it can be parallel or later.

From this phase, we move on to the real production, called “Execution”, whose phases have been established in the “Planning” and which are always subject to the “Control” phase, ie the stage in which all the features of the concept and the quality of the product are checked.

Once this phase is done and all the quality checks have been completed, the production process ends and the “Closing” phase takes place.