7. Goldsmith’s art – Iter produce of a florentine style ring – traditional vs 3D supported

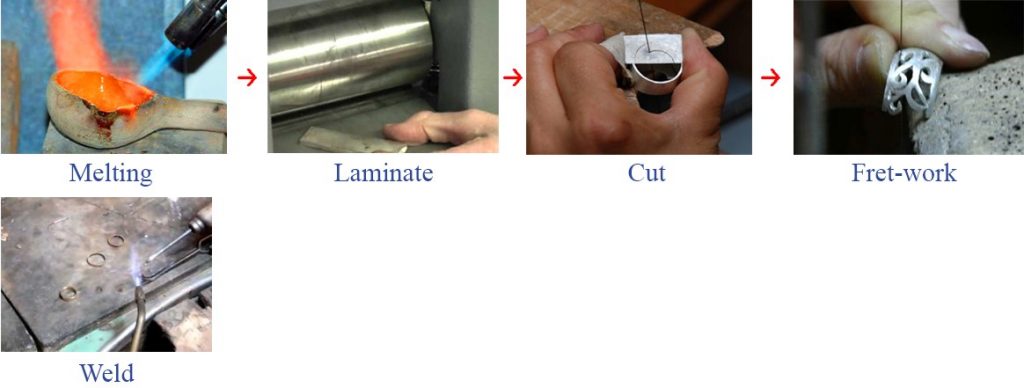

7.1 Traditional iter produce of a Florentine style ring

In the following graph, you can see the phases and production times of the ring taken as an example with the traditional method.

Image 7.1

Image 7.2

Image 7.2

As you can see the process is done completely by hand, from the preparation of the metal to the cleaning of the finished ring. A good quality goldsmith would take 7-8 days to make it.

7.2 Iter produce of a Florentine style ring (3d modeling/3d printing)

If during the production phases of the ring, it is possible to use 3D modeling software and 3D printing with meltable materials, the graph becomes:

Image 7.3

Regarding the 3d printing phase and the lost wax casting phase, it should be noted that at the same time, large quantities of pieces can be produced. Therefore, during the planning phase, it is useful to organize the work so that it can be possible to reach these phases with many models or decide to address third-party services. In this way, it can be imagined that the actual times for 3d printing and casting of a single piece are paltry.

Image 7.4

With the use of 3D modeling and 3D printing, times have halved. Without taking into account all the benefits that come into the “conception” and “planning” phases we talked about previously.

It is useful to note how the conclusive phases are the same in both processes and that they are purely manual phases, thus maintaining the product under the definition of “handicraft” and “jewel”.