8. 3D Printers – Introduction

3D printers build objects using a process known as additive manufacturing. Material is put down in layers; each layer adds to the previous layer and in turn becomes a base for the next layer.

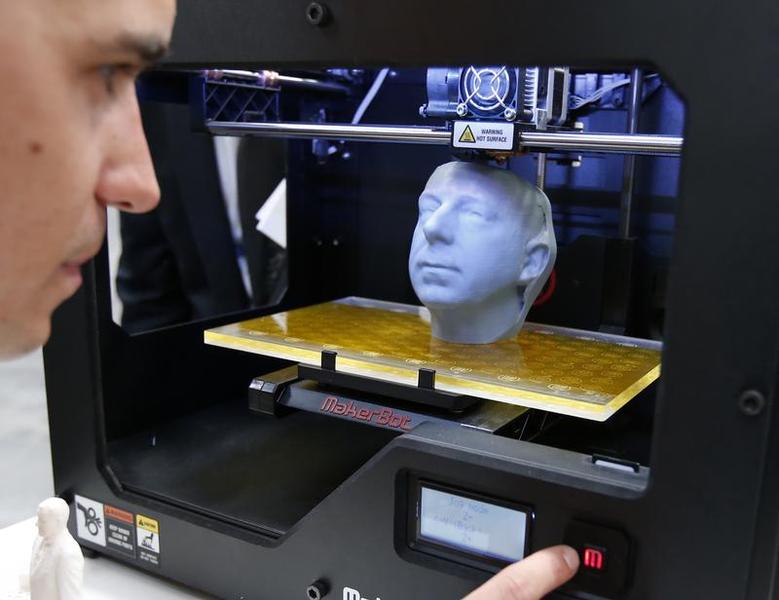

Image 8.1. [source]

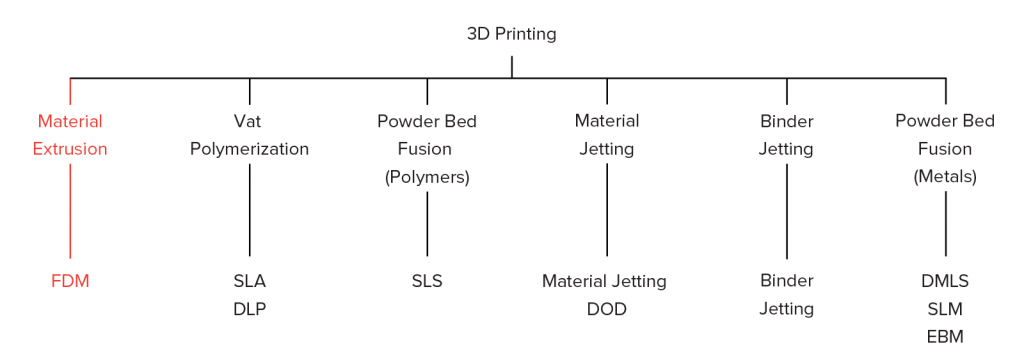

There are many types of 3D printing technologies available. Refer to the following list by https://www.3yourmind.com/blog/what-is-3d-printing for an overview:

– Binder Jetting: Inkjet print heads apply a liquid bonding agent onto thin layers of powder. By gluing the particles together, the part is built up layer by layer.

– Electron Beam Melting: A thin layer of metal powder is selectively melted by an electron beam. The parts are built up layer by layer in the powder bed.

– Fused Deposition Modeling (FDM): A plastic filament is melted and extruded through a nozzle. Parts are built by laying down layer-by-layer.

– Laser Melting: A thin layer of metal powder is selectively melted by a laser. The parts are built up layer by layer in the powder bed.

– Laser Sintering: A thin layer of plastic powder is selectively melted by a laser. The parts are built up layer by layer in the powder bed.

– Material Jetting: Inkjet print heads are used to jet melted wax materials onto a build platform. The material cools and solidifies which allows to build layers on top of each other.

– Photopolymer Jetting: Inkjet print heads are used to jet liquid photopolymers onto a build platform. The material is immediately cured by UV lamps and solidified which allows to build layers on top of each other.

– Stereolithography: A UV laser is curing a liquid photopolymer in a vat. The part is built by lowering the build platform into the vat.

Image 8.2. Some 3D printing technologies [source]

Image 8.2. Some 3D printing technologies [source]

Most 3D printers in the consumer market use thermoplastic inks in the printing process. These polymers become soft and pliable within a temperature range and then re-solidify when allowed to cool.

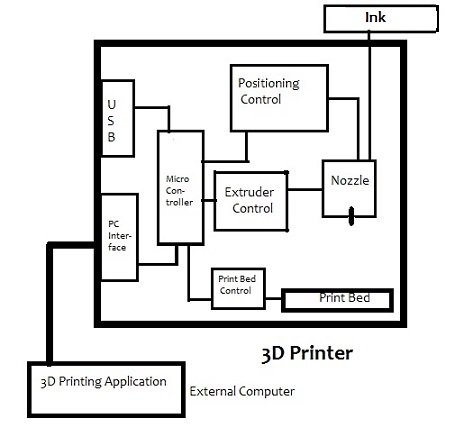

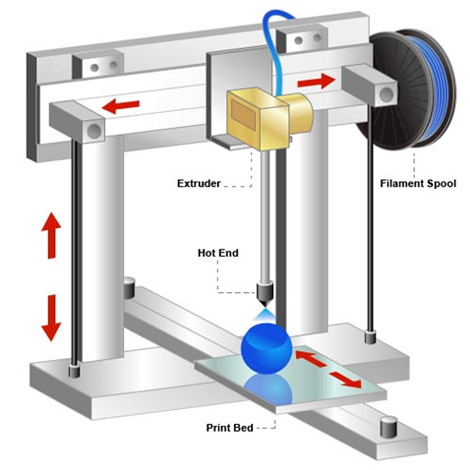

Image 8.3. A functional diagram of a 3D printer [source]

Image 8.3. A functional diagram of a 3D printer [source]

The print bed is where the object is printed. It’s usually covered with an adhesive material, and with some inks it also needs to be heated in order to minimize distortion in the printed object. The extruder temperature may be set manually, depending on the model; the nozzle position is controlled by the microcontroller, which is directed by commands in the print file.

Some printers incorporate USB ports to read files from USB drives; other printers interface to external computers, which may be running 3D print monitor and control applications. The microcontroller positions the nozzle at the X, Y, and Z coordinates needed and a specific amount of ink is set. High-precision 3D printers produce minimal wasted material.

Image 8.4. The typical parts of a 3D printer [source]

Image 8.4. The typical parts of a 3D printer [source]

For the purposes of this introduction we will focus on FDM printers (note: FDM technology is often referred to as FFF —Fused Filament Fabrication— instead).

FDM is the most widely used 3D printing technology: it represents the largest installed base of 3D printers globally and is often the first technology people are exposed to.

In this article, the basic principles and the key aspects of the technology are presented. For an extensive 3D Printer guide, you could check the following article.

Sources:

[1] https://www.allaboutcircuits.com/news/introduction-to-3d-printing-history-processes-and-market-growth

[2] https://www.3yourmind.com/blog/what-is-3d-printing

[3] https://www.3dhubs.com/knowledge-base/introduction-fdm-3d-printing#what